As of May 2012, OSHA’s hazardous chemical labeling requirements outlined in the Hazard Communication Standard, 29 CFR 1910.1200 (HCS 2012), are now in alignment with the United Nations’ Globally Harmonized System of Classification and Labeling of Chemicals (GHS).

What has changed and how does it affect me?

- Hazard classification: To ensure consistency across manufacturers, the definitions of hazard now provide specific criteria for classification of health/physical hazards and classification of mixtures

- Labels: Chemical manufacturers/importers must ensure labeling includes a harmonized signal word, pictogram, hazard statement for each hazard class/category as well as precautionary statements

- Safety Data Sheets (SDS) now have a specified 16-section format

Hazard Classification

Understanding the hazards of a chemical is an important first step in the process of establishing an effective hazard communication program. The process of hazard classification consists of four basic steps.

- Selection of chemicals to evaluate

- Collection of data

- Analysis of the collected data

- Records of the rationale behind the results obtained

The hazard classification process, as provided in the Hazard Communication Standard, has several steps, including:

- Identifying the chemical

- Identifying the relevant data regarding the hazards of a chemical

- Reviewing the relevant data to ascertain the hazards associated with the chemical

- Determining whether the chemical will be classified as hazardous according to the definition of hazardous chemical in the standard

- Determining the degree of the hazard, where appropriate, by comparing the data with the criteria for health and physical hazards

Listing all the hazard classes and categories, and the relevant data obtained for each hazard facilitates the gathering of data to document the effectiveness and completeness of the classification process.

More details on hazard classification is available in the OSHA Hazard Communication Hazard Classification Guidance.

Have questions? Give us a call at (512) 301-1451 and we’ll be happy to assist. Free one-hour consultations!

We offer training on hazardous waste topics at TrainingThatDoesNotSuck.com. Take a free demo course to see how it works or contact us for more details.

An example how to organize the documentation is shown in the table below:

Labeling Changes

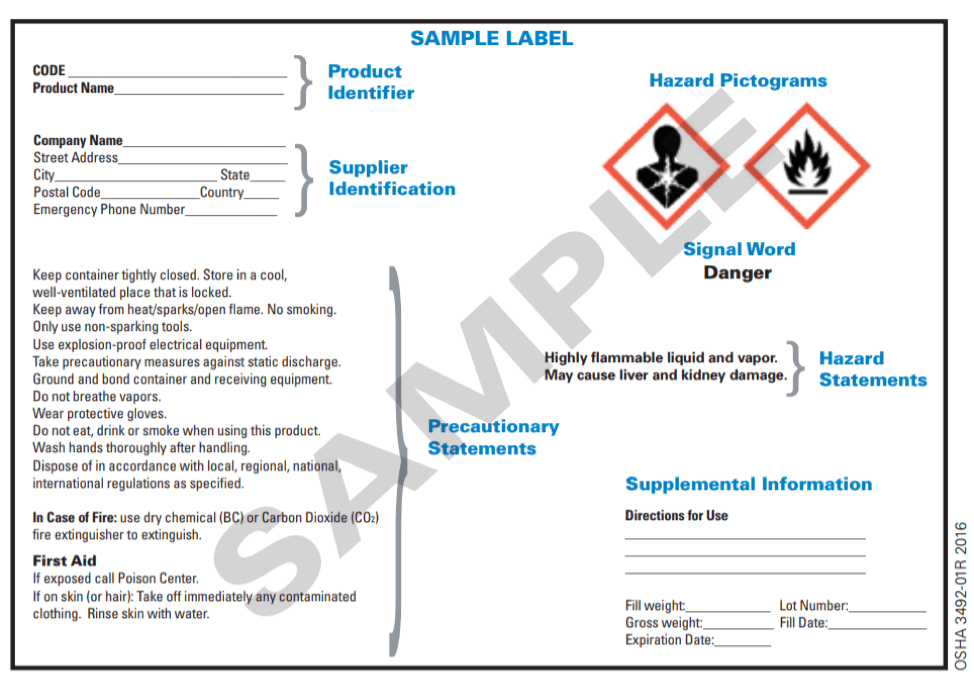

Labels requirements for shipped containers are more defined and must include

- Product identifier

- Signal word

- Hazard statement(s)

- Pictogram(s) – required to have red borders regardless of the shipment’s destination. Blank red diamonds are not permitted on the label.

- Precautionary statement(s)

- Name, address, phone number of responsible party (may be individual’s name or name of department within the company)

Within 6 months of new product information becoming available, all container labels need to be updated according to the HCS 2012 labeling requirements.

For containers used in the workplace, HCS 2012 allows employers to choose to label workplace containers either with the same label required for shipped containers of the chemical, or to use alternative labels, as long as those labels provide employees with general information about the hazards of the chemical, and the employer provides training so that employees exposed to the chemical understand the specific hazards it presents.

Other systems, such as NFPA or HMIS, are permitted for workplace containers. However, the labels have to provide at least general information regarding the hazards of the chemicals. Hazard warnings or pictograms that conflict with the HCS 2012 requirements for the chemical are not allowed on the workplace label.

Have questions? Give us a call at (512) 301-1451 and we’ll be happy to assist. Free one-hour consultations!

Safety Data Sheets (SDS)

A safety data sheet (SDS) shall include the information specified in Table D.1 under the section number and heading indicated for sections 1-11 and 16. If no relevant information is found for any given subheading within a section, the SDS shall clearly indicate that no applicable information is available. Sections 12-15 may be included in the SDS, but are not mandatory.

Table D.1—Minimum Information for an SDS

| Heading | Subheading |

| 1. Identification | (a) Product identifier used on the label; (b) Other means of identification; (c) Recommended use of the chemical and restrictions on use; (d) Name, address, and telephone number of the chemical manufacturer, importer, or other responsible party; (e) Emergency phone number. |

| 2. Hazard(s) identification | (a) Classification of the chemical in accordance with paragraph (d) of §1910.1200; (b) Signal word, hazard statement(s), symbol(s) and precautionary statement(s) in accordance with paragraph (f) of §1910.1200. (Hazard symbols may be provided as graphical reproductions in black and white or the name of the symbol, e.g., flame, skull and crossbones); (c) Describe any hazards not otherwise classified that have been identified during the classification process; (d) Where an ingredient with unknown acute toxicity is used in a mixture at a concentration ≥1% and the mixture is not classified based on testing of the mixture as a whole, a statement that X% of the mixture consists of ingredient(s) of unknown acute toxicity is required. |

| 3. Composition/information on ingredients | Except as provided for in paragraph (i) of §1910.1200 on trade secrets: |

| For Substances | |

| (a) Chemical name; | |

| (b) Common name and synonyms; | |

| (c) CAS number and other unique identifiers; | |

| (d) Impurities and stabilizing additives which are themselves classified and which contribute to the classification of the substance. | |

| For Mixtures | |

| In addition to the information required for substances: | |

| (a) The chemical name and concentration (exact percentage) or concentration ranges of all ingredients which are classified as health hazards in accordance with paragraph (d) of §1910.1200 and | |

| (1) Are present above their cut-off/concentration limits; or | |

| (2) Present a health risk below the cut-off/concentration limits. | |

| (b) The concentration (exact percentage) shall be specified unless a trade secret claim is made in accordance with paragraph (i) of §1910.1200, when there is batch-to-batch variability in the production of a mixture, or for a group of substantially similar mixtures (See A.0.5.1.2) with similar chemical composition. In these cases, concentration ranges may be used. | |

| For All Chemicals Where a Trade Secret is Claimed | |

| Where a trade secret is claimed in accordance with paragraph (i) of §1910.1200, a statement that the specific chemical identity and/or exact percentage (concentration) of composition has been withheld as a trade secret is required. | |

| 4. First-aid measures | (a) Description of necessary measures, subdivided according to the different routes of exposure, i.e., inhalation, skin and eye contact, and ingestion; (b) Most important symptoms/effects, acute and delayed. (c) Indication of immediate medical attention and special treatment needed, if necessary. |

| 5. Fire-fighting measures | (a) Suitable (and unsuitable) extinguishing media. (b) Specific hazards arising from the chemical (e.g., nature of any hazardous combustion products). (c) Special protective equipment and precautions for fire-fighters. |

| 6. Accidental release measures | (a) Personal precautions, protective equipment, and emergency procedures. (b) Methods and materials for containment and cleaning up. |

| 7. Handling and storage | (a) Precautions for safe handling. (b) Conditions for safe storage, including any incompatibilities. |

| 8. Exposure controls/personal protection | (a) OSHA permissible exposure limit (PEL), American Conference of Governmental Industrial Hygienists (ACGIH) Threshold Limit Value (TLV), and any other exposure limit used or recommended by the chemical manufacturer, importer, or employer preparing the safety data sheet, where available. (b) Appropriate engineering controls. (c) Individual protection measures, such as personal protective equipment. |

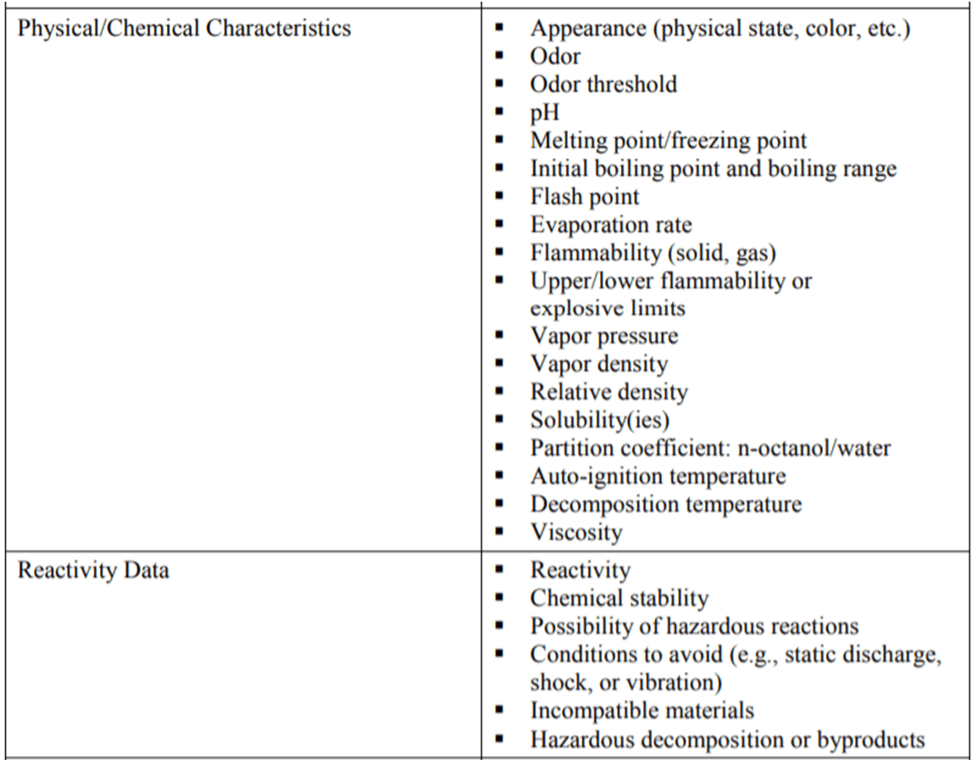

| 9. Physical and chemical properties | (a) Appearance (physical state, color, etc.); |

| (b) Odor; | |

| (c) Odor threshold; | |

| (d) pH; | |

| (e) Melting point/freezing point; | |

| (f) Initial boiling point and boiling range; | |

| (g) Flash point; | |

| (h) Evaporation rate; | |

| (i) Flammability (solid, gas); | |

| (j) Upper/lower flammability or explosive limits; | |

| (k) Vapor pressure; | |

| (l) Vapor density; | |

| (m) Relative density; | |

| (n) Solubility(ies); | |

| (o) Partition coefficient: n-octanol/water; | |

| (p) Auto-ignition temperature; | |

| (q) Decomposition temperature; | |

| (r) Viscosity. | |

| 10. Stability and reactivity | (a) Reactivity; |

| (b) Chemical stability; | |

| (c) Possibility of hazardous reactions; | |

| (d) Conditions to avoid (e.g., static discharge, shock, or vibration); | |

| (e) Incompatible materials; | |

| (f) Hazardous decomposition products. | |

| 11. Toxicological information | Description of the various toxicological (health) effects and the available data used to identify those effects, including: |

| (a) Information on the likely routes of exposure (inhalation, ingestion, skin and eye contact); | |

| (b) Symptoms related to the physical, chemical and toxicological characteristics; | |

| (c) Delayed and immediate effects and also chronic effects from short- and long-term exposure; | |

| (d) Numerical measures of toxicity (such as acute toxicity estimates). | |

| (e) Whether the hazardous chemical is listed in the National Toxicology Program (NTP) Report on Carcinogens (latest edition) or has been found to be a potential carcinogen in the International Agency for Research on Cancer (IARC) Monographs (latest edition), or by OSHA. | |

| 12. Ecological information (Non-mandatory) | (a) Ecotoxicity (aquatic and terrestrial, where available); (b) Persistence and degradability; (c) Bioaccumulative potential; (d) Mobility in soil; (e) Other adverse effects (such as hazardous to the ozone layer). |

| 13. Disposal considerations (Non-mandatory) | Description of waste residues and information on their safe handling and methods of disposal, including the disposal of any contaminated packaging. |

| 14. Transport information (Non-mandatory) | (a) UN number; |

| (b) UN proper shipping name; | |

| (c) Transport hazard class(es); | |

| (d) Packing group, if applicable; | |

| (e) Environmental hazards (e.g., Marine pollutant (Yes/No)); | |

| (f) Transport in bulk (according to Annex II of MARPOL 73/78 and the IBC Code); | |

| (g) Special precautions which a user needs to be aware of, or needs to comply with, in connection with transport or conveyance either within or outside their premises. | |

| 15. Regulatory information (Non-mandatory) | Safety, health and environmental regulations specific for the product in question. |

| 16. Other information, including date of preparation or last revision | The date of preparation of the SDS or the last change to it. |

[77 FR 17884, March 26, 2012]

Training Requirements

According to the rule, employers needed to conduct employee training on the new label elements and safety data sheets format by December 1, 2013.

- Label elements

- What information is on the new labels and how to use it

- Product identifier, signal word, hazard statement(s), pictogram(s), precautionary statement(s), and name, address and phone number of the responsible party

- General understanding of how the elements interact

- Danger means a more severe hazard within a hazard class

- Warning is for the less severe hazard

- Safety Data Sheet Format

- Standardized 16 section format and the type of information they would find in the various sections

- What information is on the new labels and how to use it

It’s important for employers to go beyond general awareness in their employee training programs. Implement procedures to ensure employees are promptly trained on new hazards/substances and routinely review HCS 2012 labels, pictograms and SDS content to increase employee familiarity with the information.

Compliance Check – The Biggest Challenges

Overall, the biggest challenge with the new requirements is access to updated SDS. Authoring updated SDS, reclassifying chemicals and finding suitable GHS labeling solutions are also impacting compliance progress.

As of December 1, 2015, manufacturers and importers of hazardous chemicals must provide HCS 2012 compliant labels and SDS for every individual container. Existing stock packaged for shipment prior to June 1, 2015 that are HCS 1994-compliant labeled may be shipped without re-labeling. Businesses that repackage/blend/mix hazardous chemicals or distributors of hazardous chemicals must follow the same labeling guidance as manufacturers and importers.

What is Reasonable Diligence & Good Faith and Why is it Important to Me?

In determining compliance with HCS 2012, consideration will be given to what steps were taken to obtain the necessary information through reasonable diligence and good faith, so documentation of efforts is a critical element. Documentation supporting compliance efforts should include:

- oral and written communications directly with the upstream supplier

- efforts to find info through alternative sources

- a written account of communications with distributers

- defined course of action to make required changes

Manufacturers or importers should be able to provide a clear timeline when they expect to comply with HCS 2012 to meet the Reasonable Diligence & Good Faith test. Distributors should be able to present documentation of any and all communications with the manufacturer or importer regarding reasons for noncompliance with HCS 2012.

More information on HCS 2012 and its requirements can be found on the OSHA website at https://www.osha.gov/dsg/hazcom/.